Every time a purchase of an analytical system for a Scanning Electron Microscope (SEM) is made, one of the key considerations is future-proofing the system or, to put it another way, ensuring that there is sufficient capability so that unforeseen applications can be addressed. I have often heard stories of new users coming to utilise a system and very quickly starting to ask questions about extending its capabilities even further.

One of the most powerful things that can be done to enhance the capability of an Oxford Instruments NanoAnalysis system including an Energy Dispersive X-ray Spectrometry (EDS) detector (such as Ultim Max or Xplore) is to add AZtecFeature to it. Many people would refer to AZtecFeature as a particle analysis tool but, in many ways, I think this is too limiting a term.

What Does AZtecFeature Do?

Fundamentally, what AZtecFeature seeks to do is automate many of the things that we, as people operating microscopes, do in our own heads. Specifically, it seeks to:

- Decide on what to analyse

- Perform that analysis, including:

- Morphological measurements of what it finds

- Compositional measurements (with EDS)

- Add a level of interpretation to the acquired data

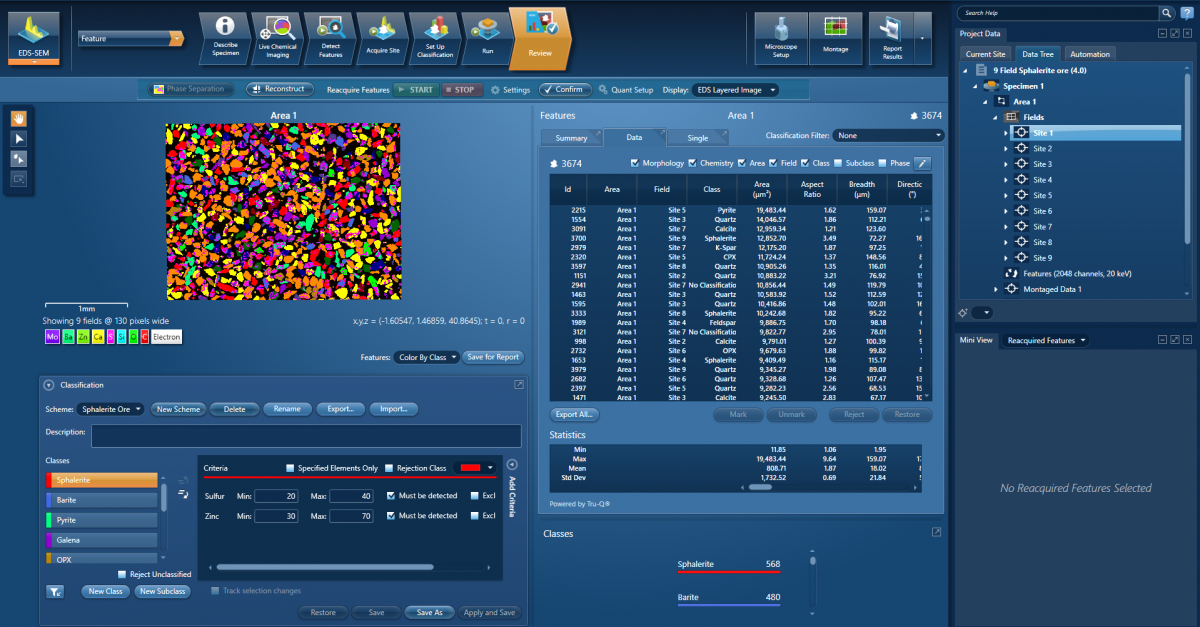

Example screenshot showing an AZtecFeature analysis of a mineral sample where grains within particles have been automatically detected, analysed for morphology and composition, and classified.

As such, AZtecFeature is ideal for analysing anything where there are discrete parts to a sample that can be visualised in an analytically equipped SEM.

What Applications Can AZtecFeature Be Used For?

In practice, AZtecFeature is often used to analyse a wide range of samples with some major examples including:

- Powders

Such as those used in Additive Manufacturing or in the manufacture of various products – e.g. batteries - Minerals

These could be single grains containing one mineral each or larger particles containing multiple grains of different minerals. Or it could be cross sections of a rock. These could be analysed in the context of mining or researching the metals and other materials that we need or as trace evidence in a forensic setting. - Forensics materials

Such as Gunshot Residue particles or any other type of microscopic forensic sample. - Wear Debris/Technical Cleanliness

Particles of varying compositions and morphologies, often captured on filters and - Environmental particulates

E.g. airborne particles collected on air filters - Inclusions in metals

E.g. sulphide inclusions in steel

And many more…

As you can see, a wide range of industries and research areas are covered by the above list (which is by no means exhaustive) meaning that a great many microscopy labs (both academic and industrial) may, in the course of their work, have a need to analyse samples along the lines of those I have mentioned. This is particularly true of laboratories that act as a central facility, serving multiple departments of a university or company or of labs that offer paid analytical services.

In such situations, it makes sense to ensure that the lab’s analytical capabilities are up to scratch in being able to extract the valuable information that may be needed now or in the future.

How Does AZtecFeature Perform?

When we add in the fact that AZtecFeature is simultaneously exceptionally fast – able to analyse in excess of 120,000 features per hour; extremely capable - with a wide range of smart functionalities to ensure that you get what you need from your samples; accurate

– being built on AZtecLive’s TruQ technologies – and flexible

enough to address all of the applications above (and more many more) then adding it to your system clearly becomes a very sensible move.

Particle detection, measurement of morphology and composition and classification all done in real time with AZtecFeature.

I hope that, in this blog, I have demonstrated to you what AZtecFeature is and how it can be of benefit to you. Of course, I don’t have space to talk about everything it can do or show many specific examples, but we do have a wide range of application notes, previous blogs, tutorials & webinars that do just that – please do have a read!