24th March 2021 | Author: Dr Haithem Mansour

EDS hardware is often the forgotten part of an EDS system, playing a much less obvious role than the software. But it has a crucial part to play in delivering fast, accurate and reliable EDS data. The “hardware” part in EDS is often referred to as the Silicon Drift Detector (the sensor), but it is much more than that. This blog post is the first in a series about EDS hardware components.

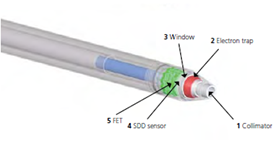

In this post, I will talk about components that come between the SDD and the sample.

Figure 1. Diagram of the components of the front part of an EDS detector

Collimator assembly

The collimator is the first component between the sample and the EDS detector. It provides a limiting aperture through which X-rays pass to reach the detector. It has an important role to ensure that only X-rays from the area being excited by the electron beam are detected and stray peaks from other parts of the microscope (stage, pole piece, sample holder…etc) are not included in the analysis. So, the collimator must be carefully designed to make sure no stray peaks are detected. If an EDS detector has no collimation, don’t be surprised to detect elements coming from other parts of the microscope like Al, Fe, Zn and Cu.

Electron trap

In addition to X-rays, electrons pass through the collimator and if not stopped could reach the SDD sensor. This could cause radiation damage to the sensor. Electrons that penetrate the detector cause background artefacts and overload the measurement chain. The yellow spectrum in Figure 2 is an example of the typical background artefact ‘hump’ shape caused by backscattered electrons.

Figure 2. Spectrum with background artefact due to BSE (yellow) compared with a spectrum collected under similar conditions (orange), where no BSE are entering the detector, and the background is made up only of the X-ray bremsstrahlung.

The role of the electron trap (normally a pair, or array of permanent magnets) is to deflect any electrons which pass through the collimator by enough to stop them entering the detector. Electron traps are the perfect component for this task as they do not reduce X-ray transmission, unlike other solutions such as electron filters.

Window

The window provides a barrier to seal the vacuum inside the detector while being as transparent as possible to X-rays. A good window needs to have high X-ray transmission, high vacuum tightness and mechanical strength, as it needs to be resistive to pressure changes within the chamber, as well as particle impacts (ballistic damage). There are different types of window materials used in EDS detectors such as beryllium (Be), high performance polymers, and silicon nitride.

Be windows are highly robust but strongly absorb low energy X-rays meaning that only elements including and heavier than sodium (Na) can be detected. In addition, Be is toxic and poses a potential health risk that requires safety procedures during manufacturing and manipulation.

High performance polymers and silicon nitride windows can be made much thinner than Be windows and therefore are transparent to much lower energy X-rays, allowing the detection of X-rays down to around 100eV. As these windows are too thin to be self-supporting, they are mounted onto a supporting grid to withstand the pressure difference between the detector vacuum and vented microscope chamber at atmospheric pressure.

Thanks to their greater transmission, thin windows have largely replaced Be windows in EDS detectors.

In instruments that operate at better vacuums, like FEG-SEMs, UHV SEMs and TEMs, it is possible to use windowless detectors which allow for even more transmission of light elements into the detector. Windowless detectors require protection during plasma cleaning, ion milling and safety circuits that ensure they will not be cooled when the microscope is vented to atmosphere.

For example, the windowless Ultim Extreme detector works in an SEM under specific experimental conditions to achieve high low-energy sensitivity for the detection of light elements (e.g. Li) or achieve very high spatial resolution (<10nm) working at very low beam energies (less than 3kV).

Hopefully, this blog has given you an overview of importance of the collimator, electron trap and window in an EDS detector and the effect that these components have on EDS performance, data quality and reliability. It’s essential that your detector is optimised with the correct hardware that matches your requirements. In my next post in this series, I will discuss the SDD sensor, FET and cooling system. Join our mailing list to be updated as our blogs go live each week.

Join our mailing list