In the burgeoning landscape of carbon capture and storage (CCS), textural and chemical analysis of reservoir rocks is vital for selecting the most appropriate injection sites. Join me as we take a sneak peek at our forthcoming application note, delving into the impact of BEX technology on one of the UK’s leading CCS projects. Together, we will explore how researchers are leveraging Oxford Instruments technology to understand CO2 behaviour and interactions within proposed reservoir rocks, helping push towards making CCS a reality.

Carbon capture and storage, why do we need it...?

The emission of greenhouse gases resulting from human activities is projected to wield a profound influence on our planet's climate, oceans, and ecosystems if current production rates persist. Among these gases, carbon dioxide (CO2) emerges as a leading contributor, primarily generated as a by-product of industrial processes. With the global community intensifying efforts to attain net-zero emissions targets by 2050, the imperative for innovative technologies capable of mitigating CO2 output becomes ever more important.

CCS emerges as a pivotal technology in the battle against CO2 emissions. This rapidly advancing domain presents a compelling strategy: capturing CO2 from industrial sources and/or directly from the atmosphere, then securely sequestering it underground beneath impermeable layers of rock. Within the reservoir, the CO2 can be housed in the rocks void spaces (pores) or dissolved into saline pore water, forming carbonic acid, which subsequently reacts with minerals in the reservoir rock to create new carbon-bearing compounds. A combination of these traps prevents CO2 release to the surface thwarting it’s greenhouse effect. The magnitude of the challenge is underscored by independent energy transition assessments, which stipulate that achieving the Paris Agreement's goal of limiting global warming to 1.5 °C necessitates annual reductions of 7.2 billion tonnes of CO2 through CCS by 2050 (Wood Mackenzie, 2023).

The Acorn CCS project

A collaboration between geoscientists from the Cambridge Arctic Shelf Programme (CASP), a non-profit independent geological research organisation, and the University of Manchester is elevating geomechanical and geochemical models to assess the carbon capture and storage (CCS) potential of Cretaceous sandstones beneath the North Sea, United Kingdom. This entails plans to inject CO2 approximately 2.5 kilometres below the seabed, slated to commence in 2030.

However, accurately predicting the storage potential, flow and interaction of the CO2

reservoir rock demands accurate quantification of:

- Mineral Abundance: The abundance of reactive minerals, such as feldspar or calcite, impacts the amount of CO2 mineralisation.

- Mineral Composition: The composition of minerals governs their reactivity rates, e.g. calcium-rich feldspars exhibit accelerated reactivity compared to their sodium-rich counterparts.

- Mineral Surface Area: Faster reaction rates are facilitated by greater surface areas.

- Rock Porosity and Permeability: These features quantify the total void space (porosity) within the rock and their interconnectivity (permeability).

Ideally, a reservoir rock should exhibit substantial levels of porosity and permeability to permit large amounts of CO2 storage and straightforward injection. Though reactive mineral phases present an opportunity for carbon mineralisation, too much mineralisation in a short period of time may block injection sites. Thus, the challenge to effectively predict CCS viability is significant!

How BEX works

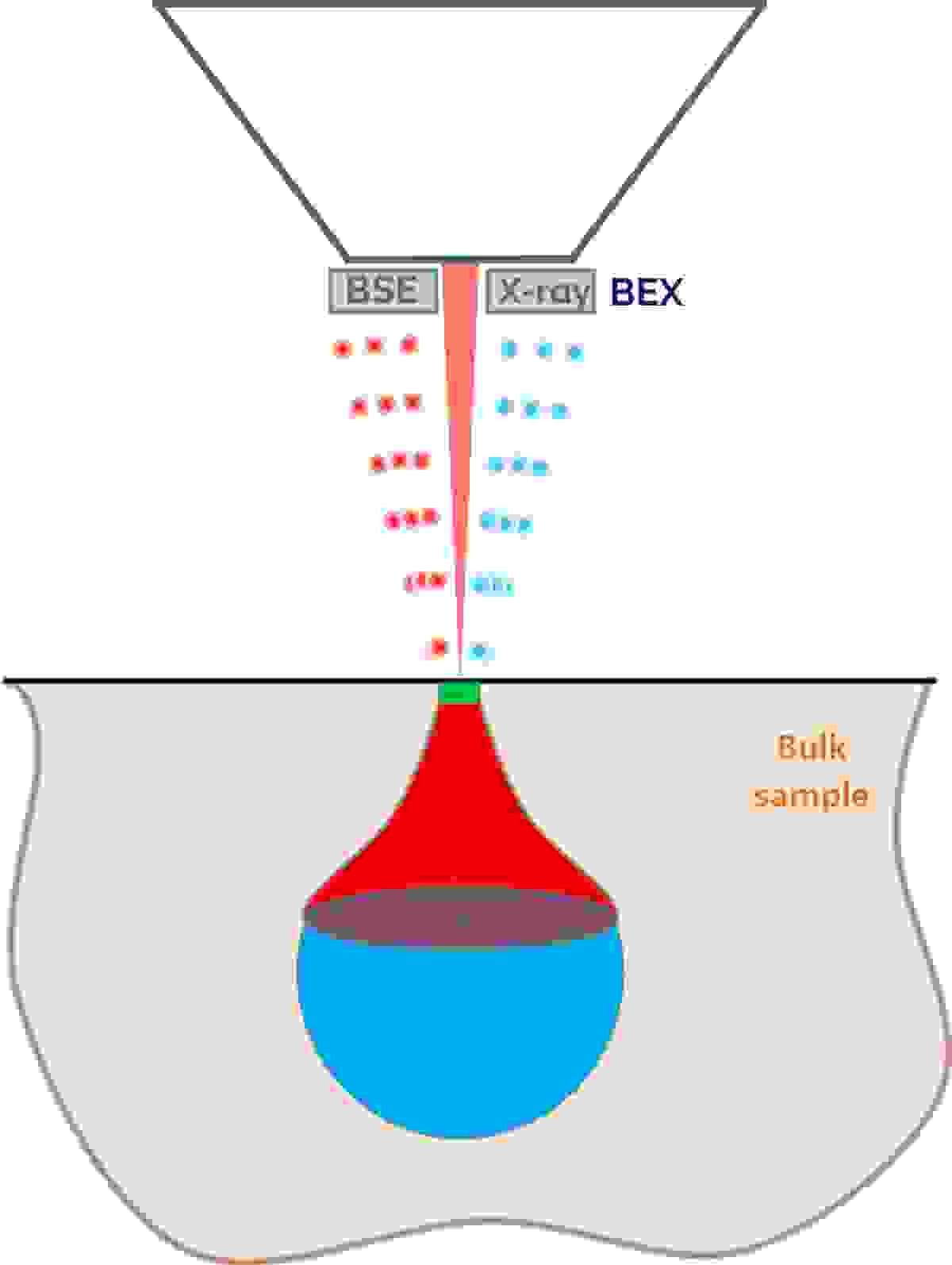

For decades, automated scanning electron microscope (SEM) analysis utilising separate backscattered electron (BSE) and energy-dispersive X-ray spectroscopy (EDS) detectors has stood as the gold standard for characterising the mineralogy, composition, and textures of reservoir rocks. Conventionally, software was configured to capture BSE images and generate separate X-ray maps at predefined intervals across the sample surface. Subsequently, these datasets were overlaid during post-processing, and individual fields were amalgamated to produce a high-resolution large-area BSE image accompanied by X-ray maps.

In this study, we undertake fully automated backscattered electron and compositional X-ray (BEX) analysis of the reservoir sandstone from the Acorn project, supplied by Michael Flowerdew of CASP. This utilises the Unity BEX and Ultim Max-170 EDS detectors operated with AZtec® 6.1 SP1. Given the imperative for both chemical and textural analysis of the sandstone, the integration of BSE and X-ray imaging via the BEX technique offers a seamless, comprehensive and time-efficient approach for sample quantification. Moreover, the innovative design of the Unity detector, positioned beneath the pole piece (Fig. 1), enables enhanced imaging of rough samples, facilitating high-quality compositional data acquisition from dry-cut and unpolished sandstone.

The extensive large-area BEX maps underwent post-processing utilising AutoPhaseMap, a software tool that facilitates clustering of X-ray spectra with similar shape, thereby grouping X-ray spectra into minerals. Notably, this approach enables the classification of resin present within the pore spaces of the sample, allowing for the determination of pore space abundance and interconnectivity (porosity and permeability).

Initial results and their implications

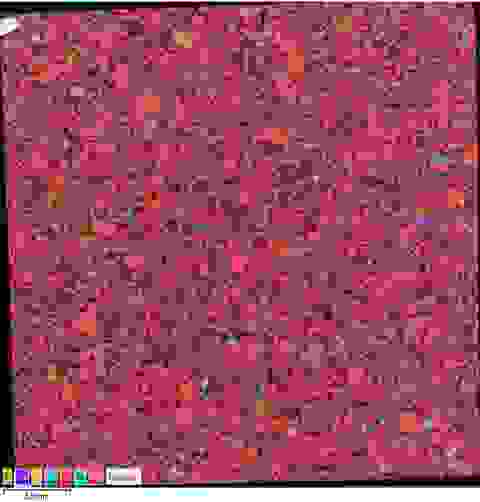

A large area BEX map of 3.75 cm2 was collected using a 20 kV accelerating voltage and 7 nA beam current in a little over 2 hours. The large area map (Fig. 2) confirms a large abundance of quartz (53%) with lesser feldspar (8.5%) and clay (3%) within the sample; however, it also indicates that about half of the feldspar is Ca and Na bearing albite, with on average 6.3% Na and 1.8% Ca.

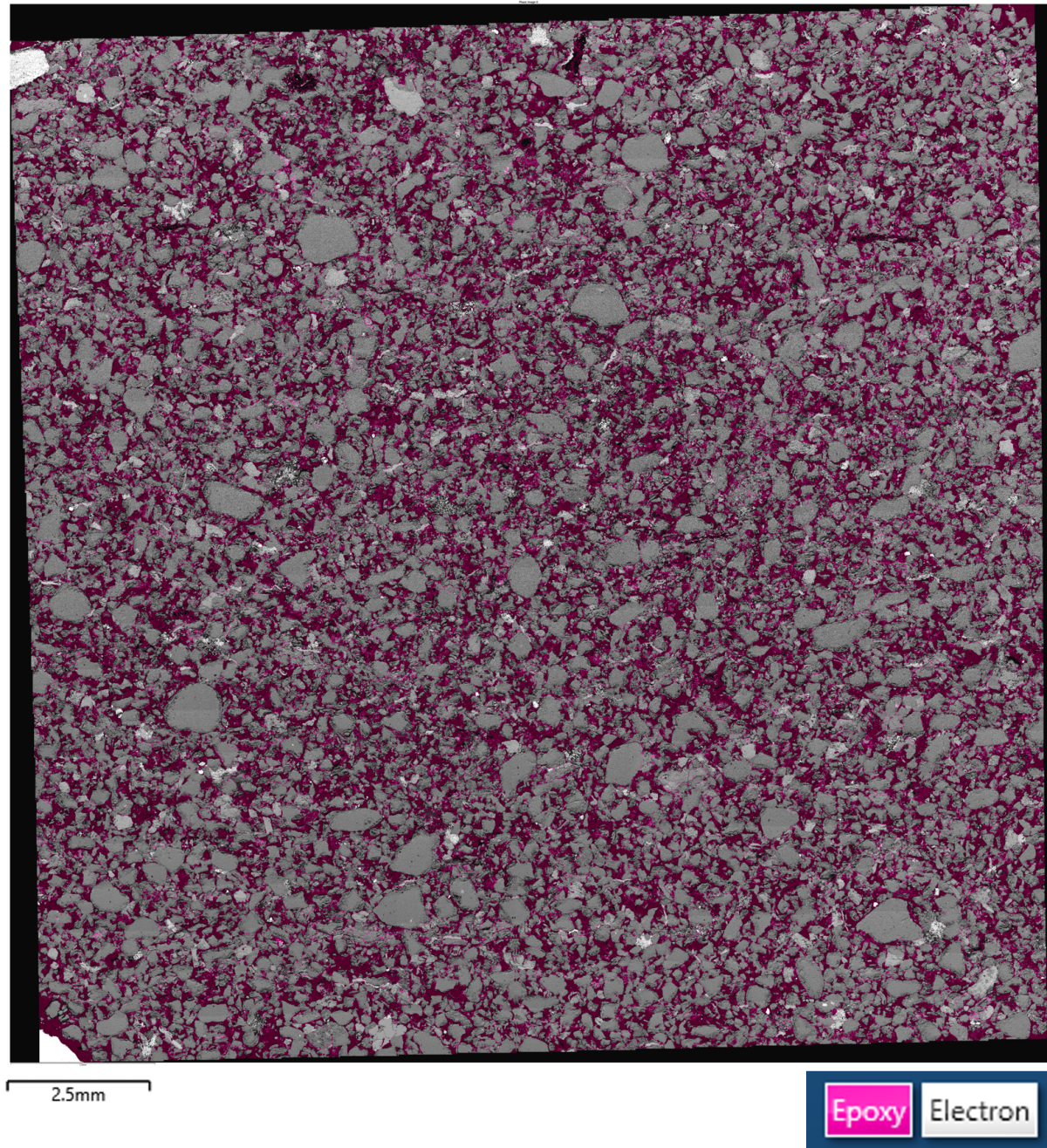

Areas between the grains of quartz and feldspar are largely dominated by clay and mud clasts, although a significant amount of pore space (>20%) is also present (Fig. 3).

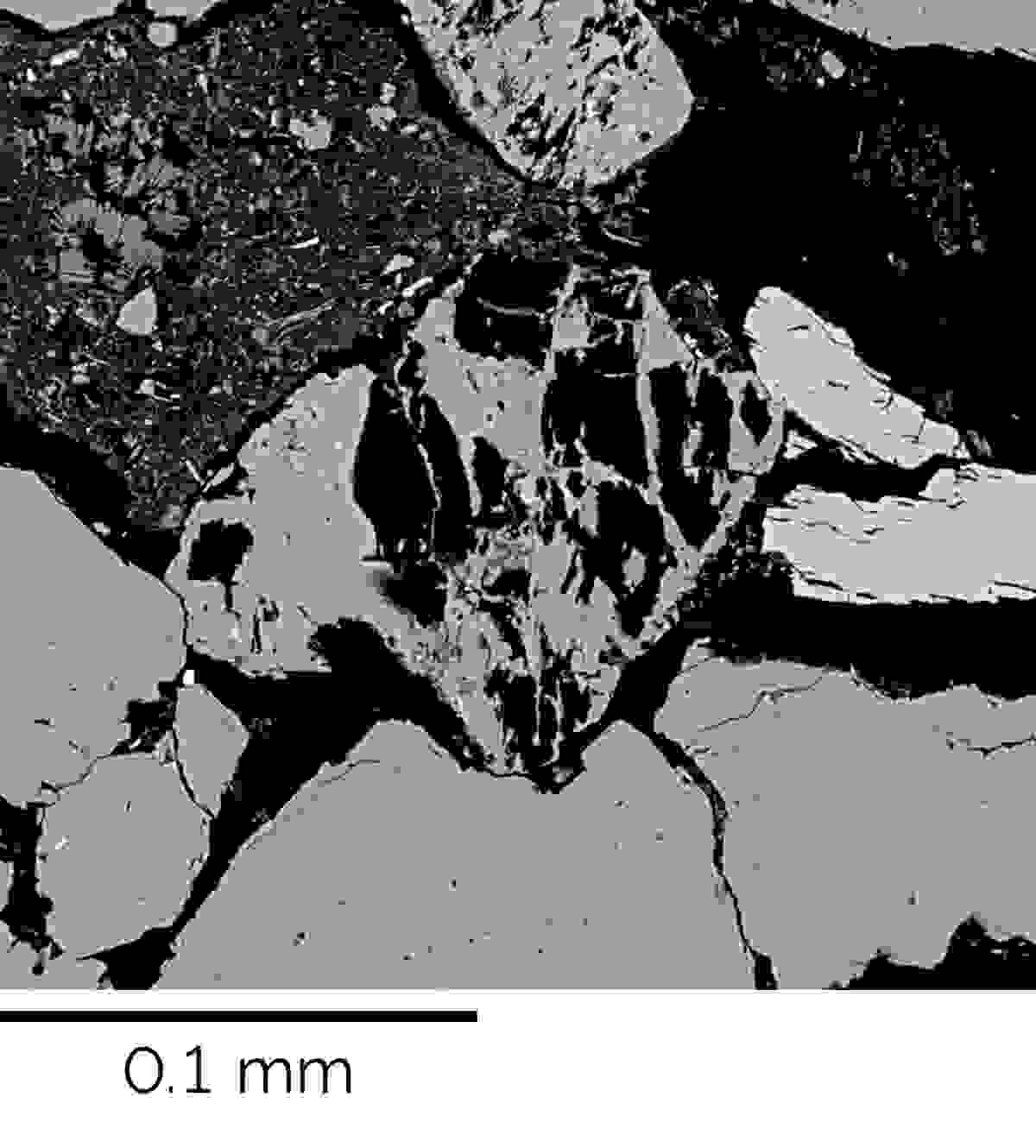

More detailed investigation of the BSE image reveals that some felspars, mainly albite, have a high surface area owing to their ‘skeletal structure’ (Fig. 4).

Significantly, this analysis reveals that the reservoir rock harbours a more substantial abundance of reactive calcium and sodium-bearing feldspar than initially anticipated. Moreover, the identification of the skeletal structure of sodium-rich plagioclase crystals suggests a significantly larger surface area than previously assumed. These findings carry considerable implications, as they could markedly accelerate CO2 reactions within the reservoir during the injection phase of the Acorn Project. While this may result in a greater proportion of the injected CO2 being permanently sequestered as new mineral phases, it may also necessitate adjustments to the numerical modelling of CO2 flow within the reservoir.

The BEX advantage

The BEX technique, powered by the revolutionary Unity detector, has unlocked critical insights into the Acorn Project's target sandstone reservoir. Seamlessly melding backscattered electron (BSE) and X-ray detection capabilities, this technique has allowed the quantification of mineral abundances, compositions and textures at an unprecedented speed (5 x quicker than the standard workflow used by CASP under equivalent operating conditions!). With its lightning-fast acquisition times and flexible working conditions, Unity has ushered in a new era of rock imaging, empowering researchers at the forefront of CCS research to maximise their instrument time.

Want to find out more, stay tuned for our upcoming application note!