Almost all nanomanipulators are installed on a focussed ion beam instrument (FIB) and used during the process of generating lamella samples for analysis in a Transmission Electron Microscope (TEM).

How is a lift out lamella prepared?

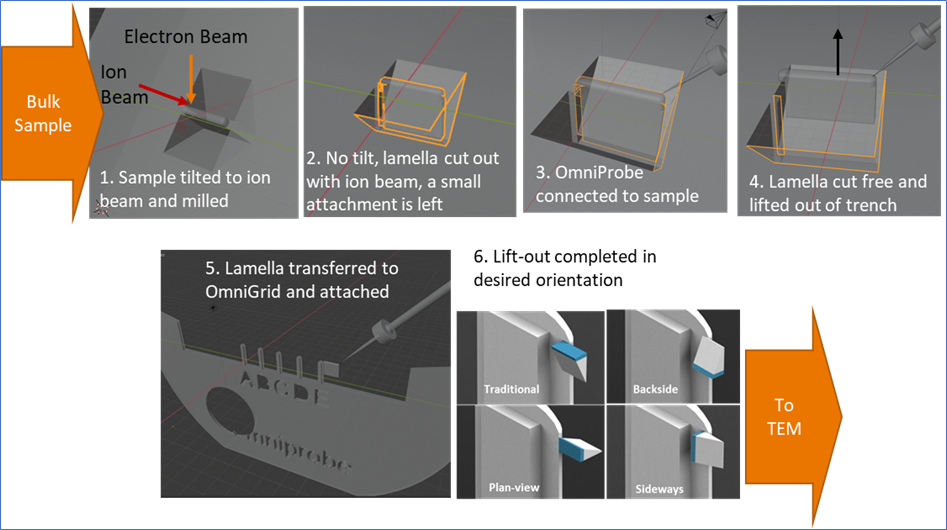

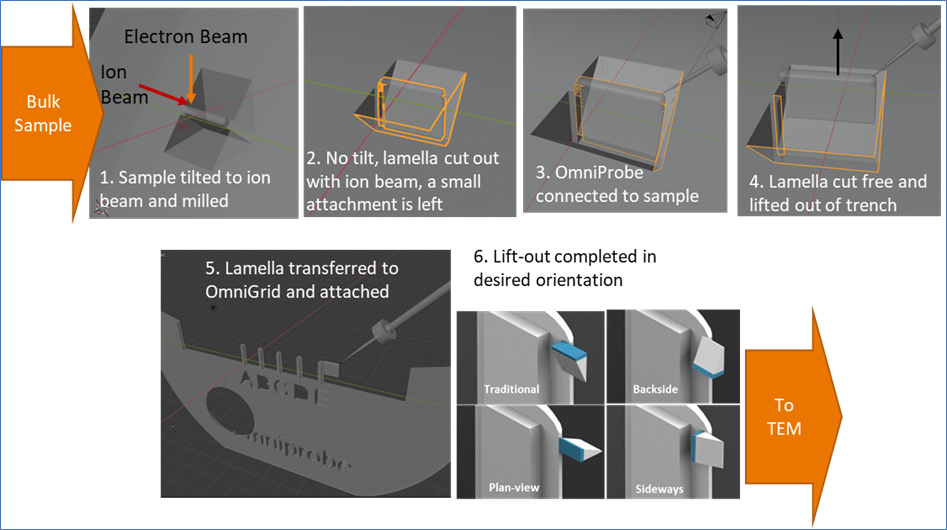

In order to prepare a lamella from a bulk sample, the FIB is typically used to cut trenches whereby a cross section lamella is generated. The lamella is then attached to the manipulator, cut free from the bulk sample (released) and lifted out of the sample. Then a grid is brought into position, and the manipulator is used to position and hold the lamella in place while the lamella is being attached to the grid. Final steps involve cutting the lamella free from the probe tip and thinning the lamella sample before transfer to TEM, as illustrated in Figure 1.

Figure 1 - General site-specific cross section lamella lift out workflow.

The details of the above-described process will depend on the instrument (geometries) and on the requirements to the analysis done in the TEM - how the lamella is to be oriented in the TEM and whether the thinning step requires a certain orientation to avoid milling artefacts.

What is required of the nanomanipulator?

The application of TEM sample preparation can be quite complex, however in terms of requirements related to the nanomanipulator it is fairly simple.

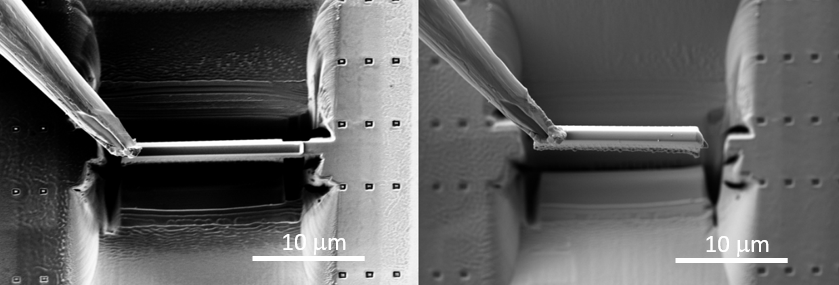

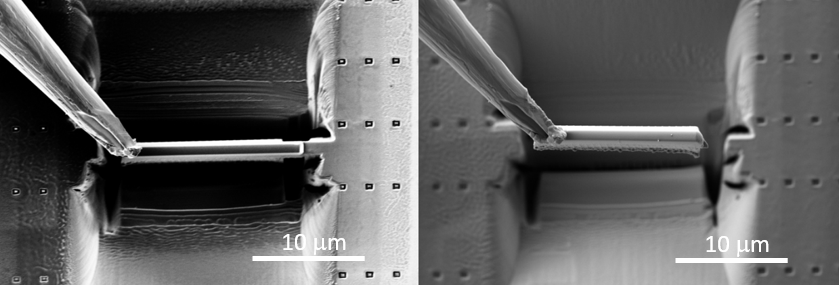

The first critical step is to make contact between the probe tip and lamella, then hold the tip in position while the tip is attached to the lamella and the lamella is then cut free from the sample. This requires that the probe movements are intuitive and predictable, so that the lamella is not accidentally damaged.

Attachment between probe tip and lamella (or later the lamella and grid), made using a gas injection system (GIS), can take minutes to deposit. While this happens, it is important for the probe to be stable, movements or drift will lead to a poor attachment potentially resulting in dropping the lamella.

The lift out step itself is presenting relatively high risk to the lamella, it is important for the movements to be intuitive to avoid knocking the lamella against the sides of the trench during the lift out. It means that the movements must be simple and linear so that single axis movements, relative to the sample surface, can be used. This means that the software needs to be intuitive and automatically link the movements to the view in the electron and ion beam images, regardless of the sample tilt.

Figure 2 - Probe attachment and lamella lift out

Despite the lift out and transfer of a lamella from a bulk sample to a grid being a relatively simple process, it has significant requirements related to the manipulator and the control software.

The answer

To answer the question in the title - not all nanomanipulators are equal and their performance specifications actually directly relate to the likelihood of successful TEM sample preparation.

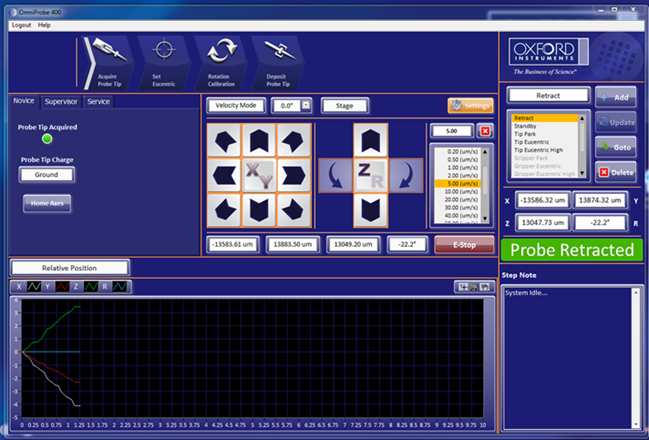

The OmniProbe nanomanipulators are controlled from a simple user interface, the directional movements are linked to the electron and ion beam images, making it very intuitive to use. It doesn’t matter what tilt angle you lift out your lamella, as you can specify the tilt angle in the software and the manipulator will move in relation to that angle. This can be very useful if you use different angles for different workflows or use multiple angles in one workflow. The stability of the probe and the linearity of the movements are part of the specifications, making all OmniProbe systems easy to use.

Figure 3 - OmniProbe software, simple and intuitive movement controls